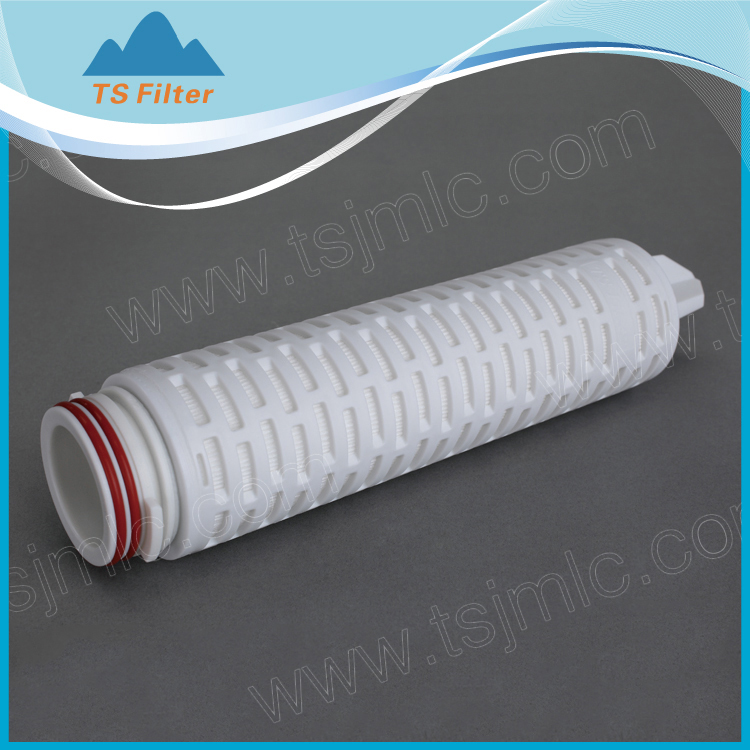

Factory China PTFE Pleated Filter Membrane as Water Filter Membrane for Filtration

Our primary goal is always to offer you our customers a serious and responsible company relationship, providing personalized attention to all of them for Factory China PTFE Pleated Filter Membrane as Water Filter Membrane for Filtration, Your inquiry will be highly welcomed and a win-win prosperous development are what we are expecting.

Our primary goal is always to offer you our customers a serious and responsible company relationship, providing personalized attention to all of them for Chinese Factory Made PTFE Pleated Filter, Strong infrastructure is the want of any organization. We have been backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our products and solutions worldwide. To maintain smooth work flow, we’ve sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we are able to accomplish voluminous production without compromising upon the quality.

◆Naturally hydrophobic PTFE membrane with excellent porosity, high low rate

◆Absolute rating, filtration efficiency ≥99.99%, Up to 0.01 micron in gas sterile

◆Low pressure drop and long service life

◆Wide chemical compatibility, resistant to strong alkali, acids, aggressive gases and solvents

◆High temperature endurance performance

◆100% integrity tested before final assembly

◆Replace Sartorius ,Pall or Millipore Filter is available

•Compressed air, CO2 line sterile filtration;

•Tank vent, Fermentation air,

•Air filtration in aseptic packaging.

•Aggressive acids, Bases, Solvents;

•Photoresists, Etch Solutions;

Table : Typical water flow rate (10″)

| Materials Of Construction | Filter Media: | Hydrophobic PTFE membrane | ||||

| Support Layers: | Polypropylene | |||||

| Micron Rating: | 0.1, 0.2, 0.45, 0.65, 1.0, 3.0 um | |||||

| Inner core: | Reinforced Polypropylene/Stainless Steel | |||||

| Outer Cage: | Reinforced Polypropylene | |||||

| End caps: | Polypropylene / Stainless Steel Insert | |||||

| Seal Method: | Thermal Bonded, No Adhesives | |||||

| O-rings/gaskets: | Silicone, Nitrile, EPDM, Viton, Teflon, etc | |||||

| Cartridge Dimensions | Outer Diameter | 69mm(2.75”) | ||||

| Inner Diameter | 33mm(1.30”) | |||||

| Length(based on DOE end caps) | 10″- 254mm, 20″- 508mm, 30″-762 mm, 40″- 1016mm | |||||

| Filtration Area(m2) | 0.65 m2 per 10” | |||||

| Operating conditions | Normal Operating Temperature: | Up to 65℃ (140℉) | ||||

| Max.Operating Temperature.: | 90℃ (194℉) at △P≤1.0 bar (14psi) | |||||

| Max. Differential Pressure | ||||||

| Normal Flow direction: | 4.2 bar (60 psi) at 25℃ (77℉) | |||||

| Reverse flow direction: | 2.1 bar (30psi) at 25℃ (77℉). | |||||

| PH Value compatibility: | 1-14 | |||||

| Sterilization: | Steam Sterilization for 30 minutes at 121±2 ℃, 100 cycles, Autoclave 30minutes (optional) |

|||||

| Cartridge Safety | Endotoxin: | <0.25 EU/ml | ||||

| Extractables: | 0.03g / 10″ | |||||

| GRADE | PRODUCT | MICRON | ADAPTER | LENGTH | O-RING / GASKET | |

| P-PHARMACEUTICAL | IPF | 010-0.1um | AA- DOE | 10-10″ | S-silicone; N-nitrile | |

| F- FOOD & BEVERAGE | 020-0.2um | CN-226/FIN | 20-20″ | E-epdm ; T-teflon (encaptulated) | ||

| 045-0.45um | BN-222/FIN | 30-30″ | V-viton | |||

| BF-222/ FLAT SEAL | 40-40″ | How to Order?- Example | ||||

| CF-226/FLAT SEAL | 05-5″ | Pharmaceutical grade; Micron:0.45um; Length:10″ ADAPTER: DOE; Gakset: Silicone. Selection Code is: PIPF045AA10S | ||||

| EN-222 three locking ears /Fin | Other-XX | |||||

Our primary goal is always to offer you our customers a serious and responsible company relationship, providing personalized attention to all of them for Factory China PTFE Pleated Filter Membrane as Water Filter Membrane for Filtration, Your inquiry will be highly welcomed and a win-win prosperous development are what we are expecting.

Chinese Factory Made PTFE Pleated Filter, Strong infrastructure is the want of any organization. We have been backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our products and solutions worldwide. To maintain smooth work flow, we’ve sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we are able to accomplish voluminous production without compromising upon the quality.